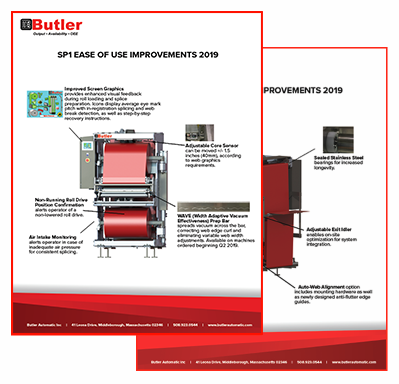

Middleboro, MA – Butler, the leader in providing OEE improvements for the packaging industry through automatic splicing, introduces several design improvements and features for the 2019 SP1 Automatic Roll splicer. The ease of use design improvements include new HMI graphics, air intake and splice prepared monitoring, web break detection and web stop, omni-directional adjustable brackets for core sensors, adjustable, integrated exit idlers, base mounted automatic web alignment, sealed stainless steel roller bearings, and a more robust mainframe nip assembly.

These improvements were designed and implemented in order to make the operator/machine interaction simpler, reduce training and maintenance time, and improve OEE (Overall Equipment Effectiveness) in our end user’s packaging lines. The new HMI graphics include enhanced visual feedback on the process and recovery instructions making operation and problem recovery easier. The web break detection, air and splice monitoring reduce operator error caused downtime. The sealed stainless steel bearings last longer, thus reducing maintenance time.

Mike Mucci, Vice President of Engineering, states that these product improvements “are the result of listening to our customers and Butler Automatic’s drive to design, deliver and support automatic roll splicing solutions which are easy to use, reliable, and perform consistently.”

With more than two thousand SP1 splicers installed on packaging lines globally, Butler Automatic is a trusted resource when it comes to increasing overall factory output by eliminating roll change downtime.