By John Gonsalves - Purchasing and Aftermarket Parts Manager

Updated April 30th, 2019

Lean manufacturing is defined as a set of management practices intended to improve efficiency and effectiveness by eliminating waste. By creating an external provider system which helps the company reduce and eliminate non-value adding activities and waste, Butler Automatic has exhibited sustained success with ongoing lean manufacturing improvements.

Analogous to what one often hears about sports teams, Butler Automatic, relies on its sourcing initiatives and performance system for external providers to find “franchise players.” These are providers who are continuously improving, so they can provide a safety net for changing customer requirements. This helps the company stay competitive in the global marketplace.

Using the external provider system to find franchise players

In some areas, long-term partnerships and agreements are critical. Like most franchise players, it may be unrealistic to expect external providers to be the best players forever. They can “go into a slump” or their performance can change due to a variety of factors that arise in the fast-changing manufacturing environment.

Scouting doesn’t mean mistreating the star players, but it does mean always looking out for the best interests of the company. And, a bit of extra competition usually does not hurt. While most companies have their “key providers,” scouting permits a focus on building up the weaker ones. The goal is to constantly upgrade external provider talent to build a stronger organization, just like any scout would want to build a strong team. Lead times are short and customer demands are high, so one must always be scouting. A contingency plan or “backup bench players” can fill in when the key suppliers may be constrained.

Purchasing and material control can play a key role in the success of lean manufacturing processes. Implementation of an external provider performance system is key to ensuring the continuous improvement which lean manufacturing requires. The program features a rigorous and comprehensive supplier scorecard and periodic audits. With a focus on coaching and training, this system helps to improve manufacturing operations and on-time delivery.

The performance measurement program is similar to the analytics department or on-staff analytics expert that every major professional sports team now has. Like scouting, external provider sourcing takes a great deal of time. Monitoring their performance is the only way to do that job effectively.

How has using the external provider system benefited our customers?

After several years of implementing a lean manufacturing structure and identifying a successful external provider system, Butler Automatic has been able to define many long-term partnerships and agreements with suppliers. These franchise players have helped Butler Automatic eliminate wastes that include defects in products, excessive inventory, transportation pollution, overproduction, loss of workers, excess motion for workers, and excessive waiting time for customers.

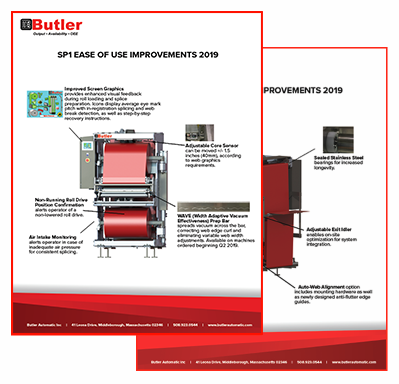

Eliminating these seven wastes, building a successful external provider system, and having backup bench suppliers on deck has brought added value to our customers in many tangible ways. One of the most positive improvements has been a reduction in spare parts line fill rate waiting time. Used as a practical metric for measuring order fulfillment performance, the term ‘line’ refers to a line on the order. A typical delivery or shipment manifest will display the name of each ordered product or item in its own line. For example, if a customer orders ten different parts, the order will have ten lines. Each line displays one of the ten products and the ordered quantity of that product. A direct result of the reduction in line fill rate, Butler’s customers have seen their parts orders ship more quickly. In 2018, 80% of all SP1 parts orders shipped on the same day that they were ordered.

Developing methods to measure supplier performance

Continuous improvement is a central tenet of lean manufacturing. Companies should focus a portion of their continuous improvement initiatives on the supply chain process for the key parts that go into the manufacturing process. Developing methods to measure suppliers’ performance would form the foundation of Butler’s initiative.

Performance measurement was by no means envisioned as an adversarial activity. Instead, working together to understand strengths and weaknesses is an attempt to understand suppliers’ problems and partner with them to develop solutions that benefit both parties.

The system involves gathering facts and performance information from Butler’s enterprise resource planning (ERP) system, including prices and on-time delivery. An outgrowth of the desire to measure supplier performance was a new understanding of the importance of giving suppliers precise, factual and accurate data on purchase orders. The desire to hold the providers accountable led to better internal departmental information on the manufacturer’s end.

The system measures performance with regard to delivery, quality and supply chain management.

Delivery is more or less a straightforward assessment of on-time delivery, and is measured based on the specific supplier’s delivery policy.

Quality measurements contain several elements. Did the supplier ship 10 parts and all 10 are good, or did they ship 100 parts, 10 of which are bad, causing disruption to the customer or manufacturing process? Incoming parts go directly to the manufacturing cell, so any problems are picked up on the shop floor. If the purchasing agent must be called out to the assembly floor because a part does not work or does not fit, or if there is any other question about the part, this causes a disruption that will be measured and factored into the performance evaluation. In other words, the performance system uses a definition of quality that includes the ability to trust that the suppliers’ parts are correct.

The quality measurement also considers whether the packing list/invoice were completely accurate to the information on the purchase order. For example, is the price exactly as noted on the invoice? If it doesn’t match, the accounts payable personnel have to obtain approval, which could slow down the manufacturing process. This falls under the sub-category administration-“perfect order.”

Supply chain management is based on price/cost, lead time and business practices. Price and cost includes terms on the PO and pricing stability. Lead time is based on the current market lead time. The business practice element may be the most important. It includes open communication, honesty, integrity and responsibility.

Capturing performance in a scorecard

The performance elements listed are captured in a scorecard, which is basically a report card that is sent to suppliers twice a year. Some elements are based strictly on data retrieved from Butler’s ERP system, while others are more subjective evaluations on how the particular element affects the business.

This scorecard was developed based on research into similar performance evaluations, and then tailored to Butler Automatic’s specific needs. The format was developed as a group effort, with the support and input from the entire management team, including the engineering manager and the director of finance and administration.

The scorecard is sent to the external providers and discussed during twice-yearly audits. The goal is to help both companies improve; the information sent is designed to actually make their job easier. It results in an overall rating, which is a weighted average of the scores achieved in each category. Unacceptable performance means action is required; marginal performance means investigation is needed; acceptable performance means the supplier meets most standards; while the preferred provider status is reserved for those achieving the highest scores. The scorecard creates a conversation in terms of how both parties can improve.

When the program started, the data available was not accurate enough to use for performance tracking. Over time, it has been revised to do so. For example, an acknowledgement step was added to the purchasing cycle. External providers now acknowledge their explicit agreement with certain data elements and understand that they will be measured on them. They get the PO, review it and update it with actual dates to ensure that the PO agrees with promised delivery dates. The acknowledgement can be either a formal computerized document or just a simple email saying that the dates look fine. The purchasing department then stores that PO acknowledgement in Butler’s ERP system.

Communication and feedback is another important factor. For example, if the PO has a delivery date of Nov. 1 and a supplier says that the order will arrive on Nov. 3, the records have to be updated and the supplier’s performance in that area is not affected. If the supplier does not communicate that the delivery will be late, their score will be reduced.

The providers that stand out usually welcome the designation and are pleased to receive kudos for performance. As noted, the process is specifically designed not to be adversarial. If an external provider continues with poor performance, they may be dropped from use, but help is offered to those who are struggling.

Results of the audits are shared monthly in a presentation to the entire Butler Automatic manufacturing team. The company measures monthly on-time performance as part of its continuous improvement initiatives; supplier performance has a direct result on the assembly floor and also effects on-time delivery. As a result of the monthly meetings, the entire company is always aware of how specific external providers are affecting on-time performance. The information is also important to the team working on the company’s ISO 9001 certification.

Performance program includes coaching and training

The goal is to get the scorecard viewed by the highest level of the company’s organization, so it becomes a part of the contractual agreement.

Since the program was established five years ago, coaching and training has become one of its main focuses. Rather than trying to hold providers’ hands to the fire, the scorecard is used to improve processes of both parties.

Another instance of developing under administration/business practice, the addition of a new element called value-add or innovation is being considered. This reflects the desire to deal with external providers who are innovative – those who come up with a better way to make things, or who look at blueprints and tell us what we could do to help them make our parts easier. Other examples of innovations include installing a new ERP or computer system to streamline operations and better meet needs.

Continuous improvement is just that – continuously striving for excellence and determining where improvements should be implemented. Lean manufacturing waste reductions directly benefit customers, suppliers and the environment. Pleased with the principles that have been integrated thus far, Butler Automatic will continue to focus on furthering lean manufacturing values throughout all areas of the business.